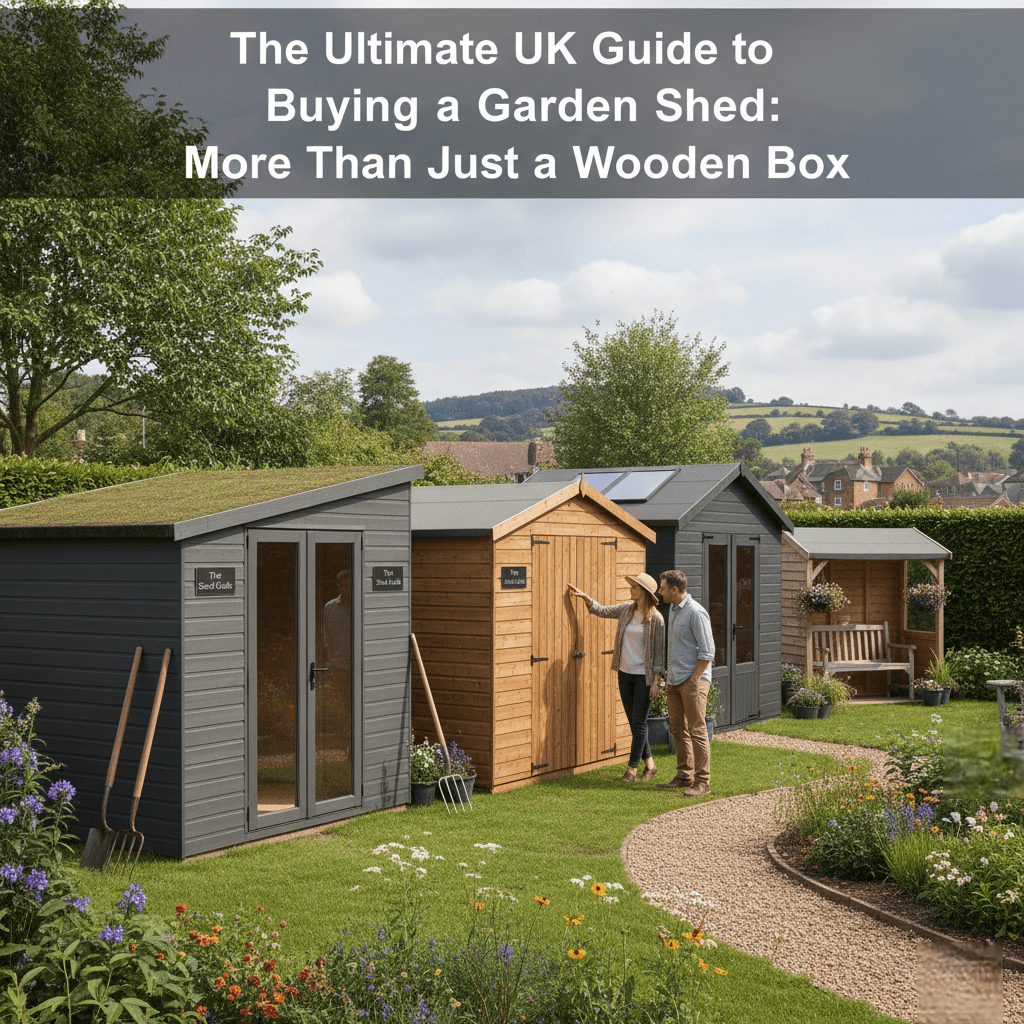

The Ultimate UK Guide to Buying a Garden Shed: More Than Just a Wooden Box

Let’s be honest, for many of us, the humble garden shed is a quintessentially British institution. It’s the silent guardian of the lawnmower, the dusty home of half-empty paint tins, and the place where spiders go on their summer holidays. But in recent years, the shed has undergone a remarkable transformation. It’s no longer just a dumping ground for garden clutter; it’s a workshop, a home office, a creative studio, a private gym, and even a tranquil retreat from the chaos of the main house. Finding sheds for sale is easy, but finding the right shed for you? That’s a different story altogether.

This guide is here to demystify the process. We’ll walk you through everything you need to consider, from the classic apex vs. pent roof debate to the nitty-gritty of planning permission and the absolute necessity of a solid base. By the end, you’ll be equipped with the knowledge to invest in a garden building that won’t just store your tools, but will genuinely enhance your home and lifestyle for years to come.

First Things First: What’s Your Shed’s True Calling?

Before you even glance at a single product page, take a moment to think about what you really need your shed to do. Its primary purpose will dictate almost every other decision you make, from its size and material to the style of its doors and windows.

- The Classic Storage Hub: If you’re simply after a secure, dry place for your garden forks, barbecue, and kids’ bikes, a simple, no-frills storage shed will do the trick. Your main concerns will be security and weatherproofing.

- The DIY Workshop: Are you a keen woodworker, a tinkerer, or a DIY enthusiast? You’ll need something more substantial. Think about a larger footprint to accommodate a workbench, good natural light from well-placed windows, and a sturdy floor that can handle heavy equipment and the odd dropped hammer. Head height is also crucial.

- The Gardener’s Paradise (Potting Shed): For those with green fingers, a potting shed is the dream. It’s a hybrid of a shed and a greenhouse, typically featuring a sloping wall of windows to let in maximum sunlight for seedlings, combined with a solid area for storing compost, pots, and tools.

- The Home Office or Studio: The rise of remote working has seen the “shoffice” (shed-office) boom. Here, insulation is king. You’ll also want plenty of windows, good ventilation, and the potential to easily run electricity for lighting, heating, and your computer. Style and aesthetics play a much bigger role here.

- The Retreat (She Shed or Man Cave): This is your personal sanctuary. A place for a comfy chair, a bookshelf, a mini-fridge, or a dartboard. It’s less about function and more about creating a cosy, personal space. Think summerhouse-style sheds with double doors and verandas.

Material Matters: The Great Wood vs. Metal vs. Plastic Debate

The material your shed is made from is arguably the most important choice you’ll make. It affects the price, durability, maintenance requirements, and overall look. There’s no single “best” material; it’s about what’s best for your needs and budget.

Traditional Timber Sheds

The classic choice, a wooden shed blends beautifully into any garden setting. But not all wooden sheds are created equal. The construction of the cladding (the interlocking panels that form the walls) is a key indicator of quality.

- Overlap Cladding: This is the budget-friendly option, where rough-sawn boards are simply overlapped to allow rainwater to run off. It’s effective but can be more susceptible to warping and draughts over time.

- Shiplap Tongue & Groove Cladding: A significant step up. The boards interlock with a small channel (the ‘shiplap’), creating a tight, weatherproof seal that is much more resistant to wind and rain. It offers a smooth, attractive finish and greater structural integrity.

- Tongue & Groove Cladding: The premium choice. The boards interlock tightly without the channel, providing the best protection against the elements and the strongest construction. This is the gold standard for high-quality workshops and garden rooms.

Pros of Wood:

- Aesthetics: Natural, traditional look that can be painted or stained to match your garden design.

- Customisable: Easy to add shelves, hooks, or even partition walls.

- Insulation: Wood is a natural insulator, making it the best choice for sheds that will be used as offices or workshops.

Cons of Wood:

- Maintenance: Wooden sheds require regular treatment with a wood preservative (every 1-5 years, depending on the treatment) to protect against rot, decay, and insect attack.

Modern Metal Sheds

Once seen as purely functional and agricultural, modern metal sheds have come a long way. Typically made from galvanised steel, they offer a sleek, contemporary look and are a great option if security and low maintenance are your top priorities.

Pros of Metal:

- Low Maintenance: They won’t rot, warp, or be targeted by pests. A simple wash-down now and then is all they need.

- Security: Metal sheds are generally tougher to break into than their wooden counterparts.

- Durability: They are fire-retardant and built to withstand harsh weather conditions.

Cons of Metal:

- Condensation: The big one. Without proper ventilation and a damp-proof membrane in the base, condensation can build up inside, which isn’t ideal for storing sensitive items. Look for models with built-in vents.

- Aesthetics: While designs have improved, some people find them less charming than wooden sheds.

- Difficult to Customise: Drilling into the walls to add shelving can be tricky and may compromise the protective coating.

Practical Plastic (Resin) Sheds

Plastic sheds, often made from high-quality UPVC or resin, are the champions of convenience. They usually come in kit form and are incredibly easy to assemble, requiring little more than a screwdriver and a bit of patience.

Pros of Plastic:

- Virtually Maintenance-Free: They require no treating, painting, or rust-proofing. They are rot-proof, immune to pests, and can be easily cleaned with a hose.

- Easy Assembly: Most plastic sheds use a simple click-and-lock system, making them a great DIY project.

- Lightweight: They are easy to handle during assembly and, if needed, can even be moved.

Cons of Plastic:

- Strength: While durable, they can be less rigid than wood or metal, particularly in very strong winds if not properly anchored.

- Customisation: Like metal sheds, customising the interior with heavy-duty shelving is not always straightforward.

- UV Degradation: Cheaper models can become brittle and discoloured over time due to sun exposure, though better quality sheds have UV protection built-in.

The Legal Bit: Understanding Planning Permission

Here’s a topic that causes a lot of confusion. The good news is that in most cases, you will not need planning permission to erect a garden shed in the UK. They are generally considered “permitted development,” provided you stick to a few key rules. Please note, these apply to England, and rules can vary slightly in Scotland, Wales, and Northern Ireland.

A shed is typically permitted development if:

- It is a single-storey building.

- The maximum eaves height (the point where the walls meet the roof) is no more than 2.5 metres.

- The maximum overall height is no more than 4 metres for a dual-pitched (apex) roof, or 3 metres for any other roof type (like a pent roof).

- Crucially: If the shed is within 2 metres of your property boundary, the maximum overall height is restricted to 2.5 metres. This is the rule that catches most people out!

- It is not situated forward of the principal elevation of your house (i.e., not in your front garden).

- The total area of all sheds, extensions, and outbuildings does not cover more than 50% of the total area of your garden.

Important Caveat: These rules do not apply if you live in a listed building, a Conservation Area, a National Park, or an Area of Outstanding Natural Beauty. In these cases, the rules are much stricter. When in doubt, always check with your local council’s planning department. A quick phone call can save you a world of hassle later.

Don’t Skimp on the Base: The Foundation of a Great Shed

You can buy the most expensive, pressure-treated, tongue-and-groove workshop on the market, but if you put it on a wonky, unstable base, you’re throwing your money away. A poor base will cause the shed’s structure to twist, doors to drop, and panels to separate, letting in the damp and drastically shortening its life.

Your base must be firm, square, and perfectly level. Here are the main options:

- Paving Slabs: A great DIY option. A bed of sharp sand and cement is laid, and slabs are carefully levelled on top. It’s ideal for small to medium-sized sheds.

- Concrete Base: The gold standard for permanence and stability. It involves creating a timber frame (formwork) and pouring a concrete mix. It’s more labour-intensive and costly but provides the ultimate foundation, especially for large workshops.

- Timber Bearers: A wooden frame that sits on level ground or concrete posts. It allows for airflow underneath the shed, which is excellent for preventing damp, but the bearers themselves must be pressure-treated to resist rot.

- Plastic Pro Base: A modern alternative consisting of interlocking grids made from recycled plastic. These are placed on levelled ground, filled with pea shingle, and provide a strong, free-draining base. They are eco-friendly and very easy to install.

Final Checks Before You Buy

You’ve decided on the purpose, material, and base. Now, when you’re comparing different sheds for sale, look closely at these details:

- Treatment Type: Is the shed ‘dip-treated’ or ‘pressure-treated’ (sometimes called ‘tanalised’)? Dip-treated sheds have a surface-level preservative and will need annual re-treatment. Pressure-treated timber has the preservative forced deep into the wood’s grain under high pressure, offering much longer protection (often with a 10-15 year anti-rot guarantee) and requiring less maintenance. It costs more upfront but saves time and money in the long run.

- Framing Thickness: The internal wooden frame is the shed’s skeleton. Thicker framing (e.g., 44x28mm) is better than thinner framing (e.g., 28x28mm) and will result in a much more rigid and robust structure.

- Floor and Roof: Cheaper sheds use solid sheet material like OSB (Oriented Strand Board) for the floor and roof. This is fine for light use but can sag and degrade if it gets wet. A Tongue & Groove floor and roof is far superior in strength and longevity.

- Doors & Windows: Are the windows real glass or a plastic alternative like styrene? Glass is clearer and more durable, while styrene is shatterproof and safer for families. Check the door construction – does it have Z-bracing to prevent sagging? Does it come with a proper lock or just a hasp and staple?

Choosing a new shed is a significant investment. By taking the time to consider your needs, research the materials, and understand the importance of a solid foundation, you can ensure you buy a garden building that will serve you well for many years, whether it’s for storing spades or starting a masterpiece.